-

HORIZONTAL BATCHING PLANTS

-

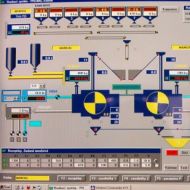

Horizontal batching plants are stationary technological devices designed for the production of concrete mixture. The technical arrangement allows to choose the type of aggregates bin according to specific conditions and location of the building site of customer.

Horizontal batching plants are stationary technological devices designed for the production of concrete mixture. The technical arrangement allows to choose the type of aggregates bin according to specific conditions and location of the building site of customer.

Silos can have various size and number by customer needs. Technology of silos is equipped with modern electronic systems. Silos are equipped with safety elements, signalization and filters. They are filled by pneumatic transport.

Aggregates and gravel are stored in chambers of storage bin. Storage bin can have various size and number of chambers. Weighing of aggregates can be proceeded in the skip conveyor or on the weighing belt conveyor according to the chosen variant

TECHNICAL PARAMETERS

TYPE TMC 20 TMC 30 TMC 40 TMC 50 TMC 80 TMC 100 Technical output [m³/h] 20 30 40 50 80 100 Volume of compacted concrete per cycle [dm³] 333 500 750 1000 2000 2500 Volume of aggregates bin [m³] 4×10 4×15 4×15 4×30 4×30 4×50 Cement silos [t] 2×30 2×60 2×80 3×100 4×120 4×120 Aggregate weigher [kg] 1000 1500 2000 2500 5000 6500 Cement weigher [kg] 200 300 450 600 1200 1500 Water weigher [kg] flow meter flow meter 200 300 600 800 Number of fraction individual individual individual individual individual individual Installed power [kW] 43 60 80 95 200 300 Voltage 400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz

-

-

Tower batching plants

-

Tower batching plants are stationary technological equipment with high performance, designed for both, the production of ready mix and the production of pre-cast mixtures for production of concrete elements and products. Their technological solutions belong to progressive among devices for the production of concrete mixtures.

Tower batching plants are stationary technological equipment with high performance, designed for both, the production of ready mix and the production of pre-cast mixtures for production of concrete elements and products. Their technological solutions belong to progressive among devices for the production of concrete mixtures.

Silos can have various size and number by customer needs. Technology of silos is equipped with modern electronic systems. Silos are equipped with safety elements, signalization and filters. They are filled by pneumatic transport.

Aggregates storage bin is placed above the mixing center, i.e. above the mixer and weighing systems. Storage bin is made by steel screwed an welded structure that is divided to various chambers, according to clients requirement.

TECHNICAL PARAMETERS

TYPE TMCV 65 TMCV 80 TMCV 100 Technical output [m3/h] 65 80 100 Volume of compacted concrete per cycle [dm3] 1500 2000 2500 Volume of aggregates [m3] 6×50 6×50 6×50 Cement silos [t] 3×100 4×100 4×120 Aggregate weigher [kg] 5000 5000 6500 Cement weigher [kg] 1000 1200 1500 Water weigher [kg] 500 600 800 Installed power [kW] 105 130 180 Voltage 400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz

-

-

Mobile batching plants

-

Mobile batching plants are technological units designed for the production of ready mix concrete characteristics its ability of fast assembly and subsequently also rapid disassembly for quick setting in a new production location. To ensure the mobility of the whole equipment, the control system is linked with control cabin by the transfer cable only.

Mobile batching plants are technological units designed for the production of ready mix concrete characteristics its ability of fast assembly and subsequently also rapid disassembly for quick setting in a new production location. To ensure the mobility of the whole equipment, the control system is linked with control cabin by the transfer cable only.

TECHNICAL PARAMETERS

TYPE TMCM 20 TMCM 30 TMCM 50 Technical output [m3/h] 20 30 50 Volume of compacted concrete per cycle [dm3] 333 500 1000 Volume of aggregates [m3] 3×7 4×10 4×15 Cement silos [t] 1×60 2×60 3×60 Aggregate weigher [kg] 1000 1500 3000 Cement weigher [kg] 200 300 600 Water weigher [kg] flow flow 250 Installed power [kW] 45 60 95 Voltage 400V 3 PEN 50Hz400V 3 PEN 50Hz400V 3 PEN 50Hz

-